| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

AVTOMATIKA VEKTOR

Novgorodsky Prospekt, 32, Building 4, Arkhangelsk / / / RUSSIA (RUSSIAN FED.)

|

Contact Info: +7 818 241-03-30

|

Hall: 6

Stand: 605 A3

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

We develop and implement high-tech automation projects for woodworking enterprises all over the world. Among our products are VECTOR log scanners, RuScan lumber quality scanner, MillLab sawing optimization web-service. We create automated control systems for all areas of sawmill from roundwood feeding to finished product packaging. The entire cycle of works is within our competence from electrical equipment design and software development to commissioning, personnel training and technical support.

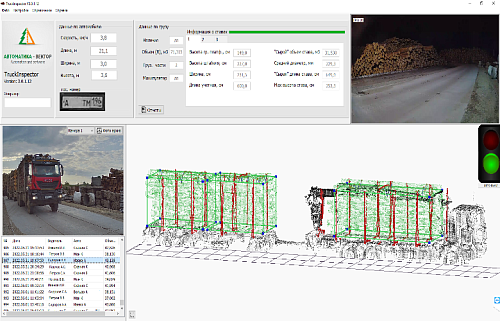

Truck Inspector hardware and software complex is designed for automatic measurement of the roundwood volume on moving vehicles with the stack method according to GOST (State Standard) 32594-2013 Round timber. Measurement methods. Measurement accuracy +/-5% is confirmed in the course of acceptance tests (when comparing, the volume obtained on the log sorting line was taken as the standard being the most accurate indicator of the actual volume of a timber batch). Most often, a deviation of only 2-3% is observed.

The Timber Tracer lumber ends scanner photographs and analyzes the ends of lumber moving on the sorting conveyor. Modern software based on neural networks processes images and provides additional information: Important parameters for automatic board quality assignment, Radial, semi-radial and tangential sawing, Refinement of lumber strength.

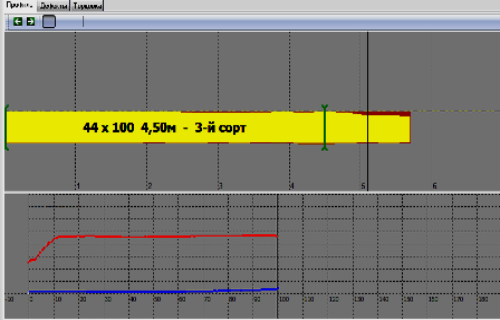

Hardware and software complexe was developed by AVTOMATIKA-VEKTOR. Actually scanner is a line of sensors, located for every 10 or 30 cm that are connected to a special computer with specialized software and have the function of optimization for clean sawn face or for timber sales value. The typical system for sorting and trimming of raw timber includes 28 triangulation sensors, located from the length of 2.4 meters and every 30 cm. The sensors are mounted above and below the board. The system reliably detects the board geometric parameters and wane regardless of the spatial orientation of the board and wane position on the board. All sensors are strictly synchronized with each other; the geometric model of the board is built into the computer s memory quite easily. Based on these data, the software calculates the various geometrical misalignments from the model parameters and does the analysis for decision making. Information from the sensors is transmitted to a computer in digital form and this allows to obtain long term repeatability and accuracy of measurements, as well as ensures a high anti-interference ability of the data channel. The scanner is mounted on a special measuring station of sorting line; the output signals from the computer control the operation of the trimmer. After scanning each board geometry and proceeding this information into the computer, the software processes the information, analyzes possible variants of board trimming and chooses the best one. Applications of such a complex allows to raise the profitability of the sawmill for 2-3% as compared to manual operation mode.

Scanner is designed to work in automated log sorting lines for contactless determination of the thickness, width and wane of the board. The thickness measurements are effected by laser triangulation distance sensors, width measurements - by impulse signals of encoder. The control unit processes the sensor signals and gives to the control system the information about board s cross-section. Configuration and calibration of scanner are made by special software. Scanner includes control unit, laser triangulation sensors of distance - 2 pcs., cables, incremental encoder, configuration software to set scanner, documentation. Main technical characteristics: Measurement of board section in one place along the length of the board. The error of thickness measurement: +/- 0.2 mm The error of width measurement: +/- 2 mm Thickness measurement frequency: 2500 Hz Communication interfaces: Ethernet, RS485 Operating temperature: -10 ... +45 degrees Celsius Power supply: 24 VDC Cross-section scanner allows you to sort timber by sections with high precision on the lines with a feed rate of up to 150 boards/min.

Software and hardware complex can be used for log sorting lines, sawing lines, board sorting lines and so on. The primary element or a source of information is a unit of the product fixed by scanner and by sensor with timing mark. If there are no events in excess of permitted time, the downtime period starts. The operator must enter the reason and close the pop-up window. The software will do the rest. The program operation is shown on the example of board sorting line. In this case, the report can be fixed and displayed both by the top (sorting line) and by the bottom (stacking machine). Automatically downtime periods are classified according to the duration and time: long-term and short-term, regulated breaks, shift change, etc. If for some reason the operator did not enter the reason for unregulated downtime, this downtime is charged to the operator. Figure 1 shows a visual representation of operating time. You can see the percentage and duration of short-term and long-term downtime periods. You can immediately determine how effective the current shift is.

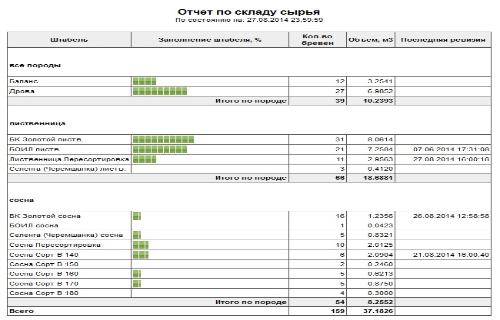

The system is designed for online gathering, storage and processing of operating data about quantity and volume of logs in the stock of raw timber. This is an additional module The Stock of Raw Timber to the main log sorting program LogSorting. Sorted logs are piled to be fed in a sawmill. Logs entering the sawmill from the indicated pile are automatically discarded from it. As a result, it is possible to track the information about the quantity and volume of logs which are stocked in each pile in the stock of raw timber online. There is also a possibility to manually adjust the parameters (log adding, moving and uploading, audit). As it should be after the audit, all further calculations about piles are held on the basis of these data.

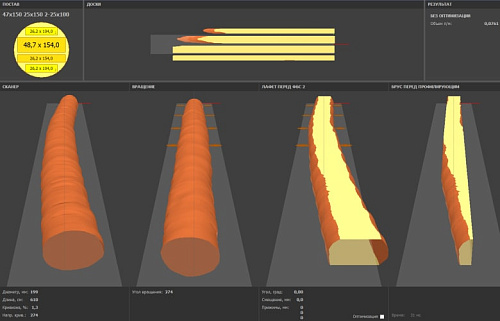

The main goal of sawmill is to get the maximum profit of raw material. Now this trend is getting stronger. If the sawmill uses old technology and equipment, it can t exist. One of the main value measures is a yield of a log. There are several ways how to improve this factor, the most effective way is the PC-based optimization of sawing on the basis of 3D modelling. In this way, the optimization operates individually for each log. The modern computer equipment allows modelling all stages of log by searching hundreds of possibilities accounting the yield of log and its cost, the allowance for edge and processing limits of equipment.

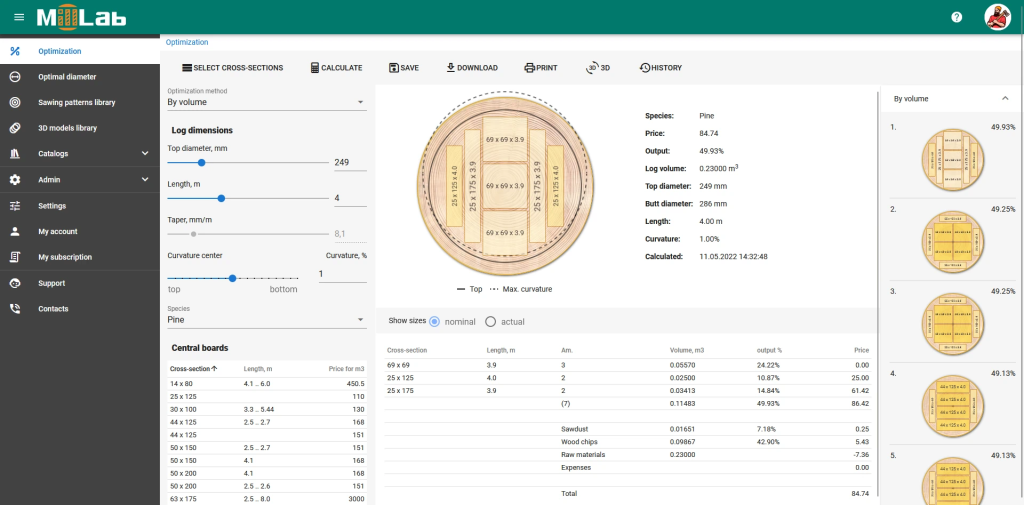

This software as well as its predecessor SawsOptimization program is designed for industrial and planning engineers of sawmill production and is a tool for sawing optimization and achieving the maximum useful output. Modern intuitive web interface reduces the time spent on learning the program and allows you to start working as soon as possible.

RuScan made by AVTOMATIKA-VEKTOR is all-in-one system which functions as lumber scanner, searching and measuring device of geometry of defects, sort use, species of wood determination, crosscutting optimization. Scanner has been successfully operating for a very long time in different regions of country from Karelia to Eastern Siberia, were sorted millions cubic meters of lumber supplied to different markets with different kinds of specific requirements. In addition to this, this scanner is able to collaborate with the program controlled crosscutting mechanisms and pockets ordering by using of general parameters and settings system. Both of these programs have advanced reporting system based on MS SQL, what is very convenient for analytics and export to other accounting systems. Clients also appreciated the convenience of reporting viewing by using the usual browser.

No represented companies found.

- АВТОМАТИКА-ВЕКТO

TR

TR