| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

AS METAL AĞAÇ MAK.SAN.VE TİC.LTD.ŞTİ.

Dudullu Organize Sanayi Bölgesi 1. Cad. No: 30/A / Ümraniye / İSTANBUL / TÜRKİYE

|

Contact Info: +90 216 415 5656

|

Hall: 8

Stand: 801-802 A

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

We re a 50 years old company working in accordance to the policies; high quality and operating performance, high effecieny and frugality. So that our production brings ease of use and trouble-free operation operation by the technical services provided. On the other hand we follow the same policies for our imported machines as a dealer-dıstrıbutor company. So that our clients have the privilege of working with a manufacturer -importer company in the same time.

TRANSFORM PLUS As standard single machine, request and are produced as a pair of trays. Standard tray size 1400 x 2500 mm dir. Tray movements made by hand. The operating cycle takes place completely automatically during Printing. in total, 3.5 +1 kg / cm2 This model works with light pressure, 0.2 mm ve 0.4 kaiığnlıg mm PVC foil in all kinds of mat and is ideal for natural veneer cover jobs. Also in the medium quality glossy PVC (high gloss) also be used to cover jobs. necessary to machine the upper plate removably mounted on the rubber-silicon membrane suspended after a few minutes. Thanks to the auxiliary air chamber, No need to install on the machine is to dismantle the membrane and membrane-membrane studies. The transition between operating formats, easily done with a button on the machine. FORMA PLUS Designed primarily as a vacuum-membrane press, this model has all the features of the Transform model. Table movements are also automatic in the Forma model, which is produced as 1400 x 3200 mm and double table as standard. Therefore, this model operates fully automatically, if desired, it is also possible to manually control the entire machine by switching to manual mode. This machine, which works with a total pressure of 6 + 1 kg / cm2, gives excellent results for all kinds of matte PVC cover and natural veneer cover works of 0.2 mm, 0.4 mm and 0.6 mm thickness. It is specially designed for high gloss cover works with a pressure of 6 + 1 kg / cm2. This ensures that glossy PVC foils that are more difficult to shape are pressed under lower temperatures. Adhesive PVC foil does not lose its brightness, surface so called the orange surface disappears and gives excellent results. GENERAL FEATURES Carries the engraved thermoplastic foil, veneer or the flat surface glued to panel. vacuum, membrane, Membrane presses the vacuum-operated in different functions. Vacuum-saving feature allows the membrane by allowing material to be used as part of pvc ıer. The oil-heated hotplates, Each serpentine or solid surface due to the special uniform heat distribution plate system is provided. Printing takes place during the operating cycle is completely automatic. For this multi-function machine is supported by a PLC. vacuum, to select the desired program type membrane or a wide variety of work modes are possible for the vacuum membrane. Memory may be made to the programs on the operating cycle and this provides great convenience for users. Different thickness and / or programs made for different types of PVC color after memorized, from now are easily installed and working memory can be initiated when desired. All Transactions 7 inch touch screen and Turkish operated was made very easy for users with visual programming. Diaphragm or membrane-pressure selection is made with a single button on the control cabinet.

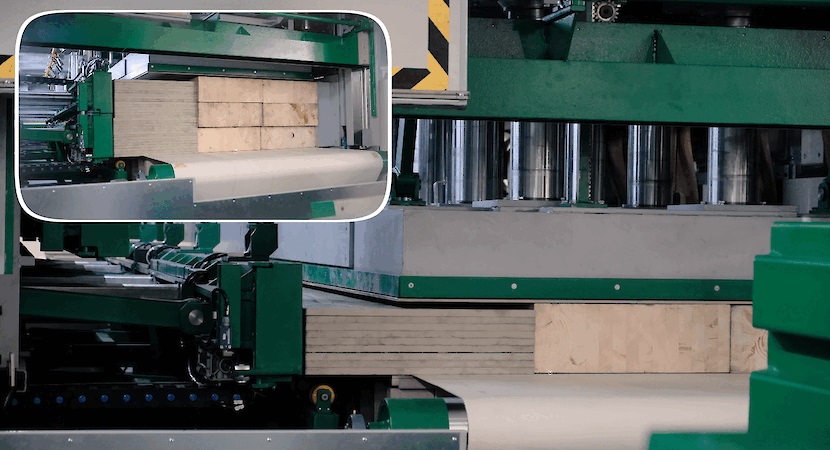

Designed for laminating solid wood, these automatic pressing lines are suitable for the manufacture of wooden beams and panels. It can be produced either as hot-plate or high-frequency heating or as cold-plate as drying request. Ideal for solid panel, laminated window joinery, CLT (Cross Laminated Timber) wooden wall production, this system operates fully automatically and can respond to large production capacities with its high performance.

-Specific pressure of 10 kg / cm, -PLC automation, -Easy to use control panel, -Fault notification messages, -Oil heated steel construction plates, -Special alloy aluminum plate on plates on request, -Fast, fast and efficient operation, -Scissor hydraulic lift (two speed), -Motorized and speed controlled material feed arm, -Precision glue spreader with two motors, four rollers, dosing adjustment and automatic washing, -The glue spreader on the rails can be easily taken out of the line for cleaning and maintenance, -Pool conveyor for resting and resting glue-applied panels, -Covered storage sections on the pool cone, -Panel placement trolley and work preparation tape, -Powerful hydraulic press with automatic loading and unloading, -Designing upon request, -3D CAD design, -3D Animation, -Full or Semi-Automatic Operating System, -PLC Control, -Lift Pusher, -Cleaning Brushes, -Glue Spreading, -Water Cleaning Disc Conveyor, -Foil Laying and Cutting, -Belt Conveyor, -Hydraulic Heated Press, -Free Roller Table.

PLC CONTROL Manual and automatic operation Automatic opening at the end of pressing Precise timepiece adjustable from 100 to 100 hours Reliable, precise control and longer operating life Extra safety functions: Stopping the pump and automatically opening the plates 2-3 cm to avoid pinching when the safety wire is pulled TETRAGON series presses can be produced with different types of plates and heating systems according to the need in order to get the best efficiency. The oil dynamic and electrical equipment is manufactured according to the latest norms in accordance with the latest inventions. The control panel is arranged to allow easy adjustment of all presses. Equipped with press pump, boiler, oil tank and pipes. Safety rope and automatic opening system available Construction Strong body structure made of steel profiles. Precise machined pressing tables with one surface. Rack and pinion gear system for stable movement of the pressing table. Hydraulic System Electrovalve controlled hydraulic system. Bypass circuit protecting machine and hydraulic system. Special, silent hydraulic pump. Hardened chrome plated hydraulic pistons. Precise machined hydraulic cylinders made of steel drawn pipe. Special sealing rings for long operating life Heat Plates Absorption tubes for homogeneous distribution of temperature throughout the plate. Hot oil serpentine that can be easily maintained in the plate. Chrome Nickel, stainless steel sheets. Oil inlet and outlet ports on each plate. Special insulation materials that prevent heat transfer to the body in the upper and lower plates. The surfaces are precisely ground and drilled in one piece. Thick, solid steel, heat plates. Hot Oil Tank and Circulation Pump Insulated, special circuit pipes and hoses that allow circulation between the oil tank, heating modules, circulation pump and heat plates. Closed system heating modules equipped with special electrical resistors for heating the oil. Special, hot oil circulation pump. Special oil tank positioned on the top of the machine.

The robotic arm can be programmed, It can be described as complex mechanical parts of the whole or a part of a robot. Today, robotic arms have become an integral part of the industry. Robotic arms lowering the minimum manpower, Reduces the error margin rate. Thereby bringing the amount of the higher levels of production, It provides a significant contribution to modern technology. Uses Robot Arm -Collection, Packaging, Palletizing, -Material Handling, -Spraying, Painting, Polish, -Automation Machine Support, -Assembly, -Gluing, Bonding.

TSM2R 2 Rollers Auto. Glue Spreading Machine -Automatic glue spreader is an indispensable machine for high quality mass production in wood industry. P-lywood, chipboard, veneer, contralite and all kinds of wood materials, fiber, rubber and plastic plates, desired width, thickness and density, provides a series of gluing. -Provides job efficiency and glue saving. -Double glue container -Independent glue thickness adjustment on each roller -Possibility to apply single or double face glue -CE (European Union Security Norm) -Safety switch-controlled safety cages that automatically stop and operate when closed on rollers -Manual washing unit with brush, movable on rollers TSM4R/2M 4 Rolls, Precise Dosage Adjustment, Auto. Glue Spreading Machine -Double or single face glue application. - CE (European Union Safety Norm). -Safety switch-controlled safety cages on rollers that automatically stop when opened and continue to operate automatically when closed.

The company has no registered brand information.

TR

TR